A leading automotive manufacturer faced frequent supply chain disruptions, inefficient inventory tracking, and manual production scheduling. They sought an AI-driven solution for real-time visibility, predictive analytics, and automated operations.

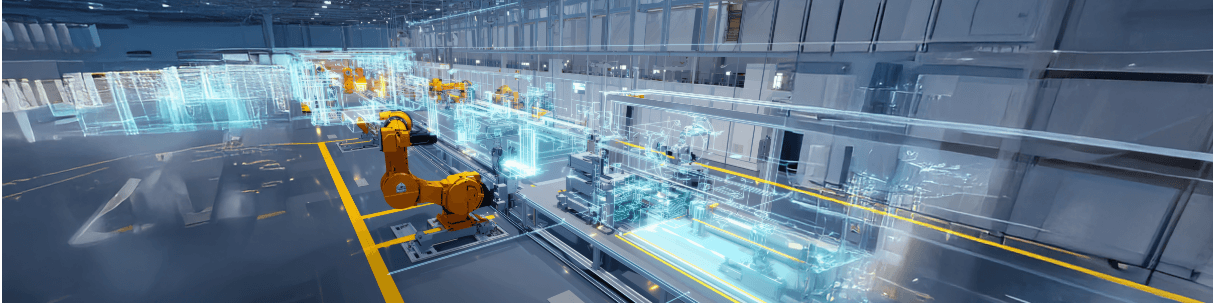

Airo collaborated with the manufacturer to deploy an Agentic AI solution that revolutionized supply chain management. Airo’s predictive analytics tools enabled real-time visibility into inventory levels and demand forecasts, identifying risks before they became bottlenecks. Intelligent agents from Airo automated production scheduling, dynamically adjusting workflows to align with shifting supply and demand patterns. This adaptive approach ensured smooth operations and allowed the manufacturer to respond rapidly to market fluctuations.

Airo’s predictive AI solution reduced production delays by 70%, improved inventory accuracy by 50%, and enhanced supply chain efficiency by 40%. The manufacturer gained agility to respond dynamically to market demands.